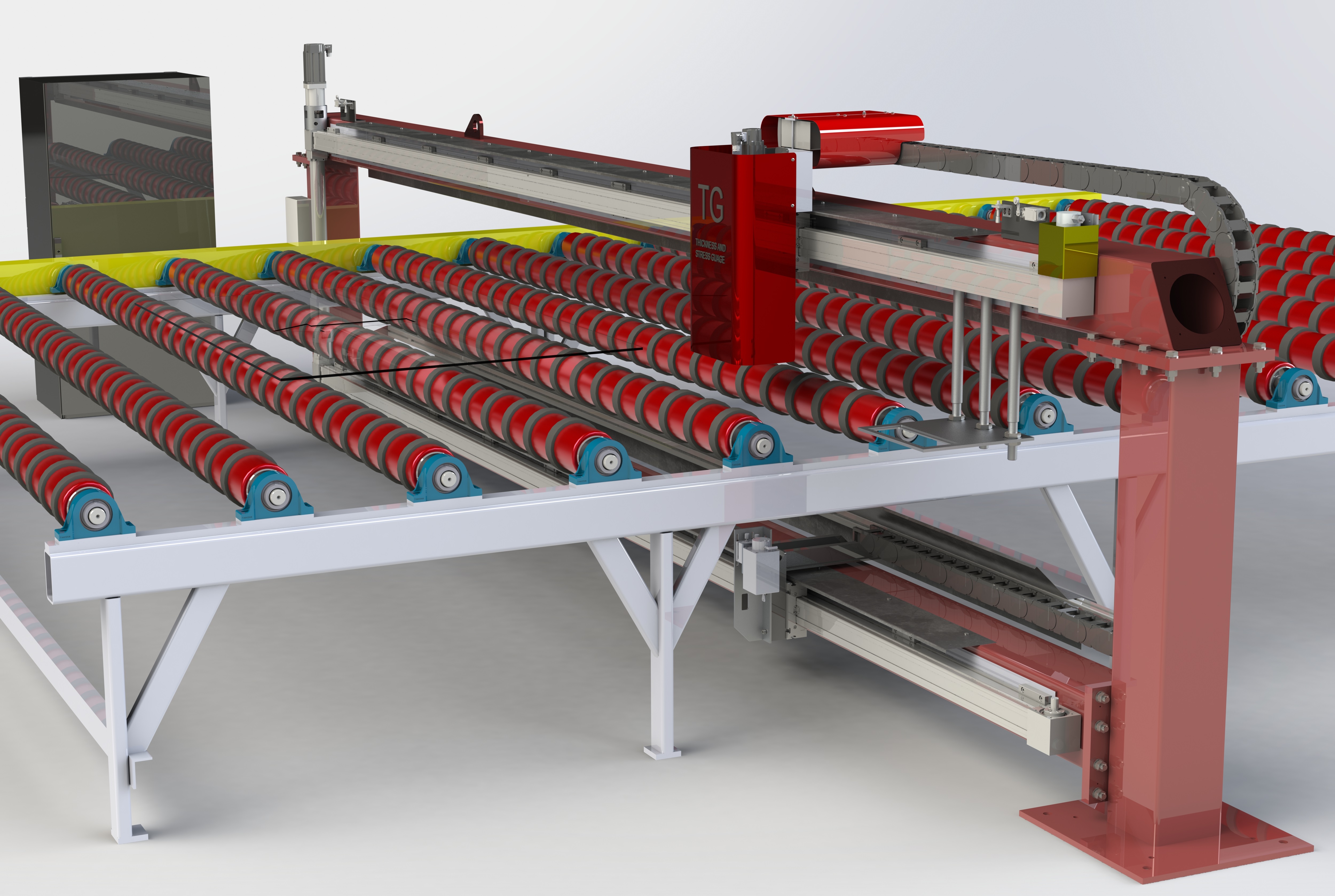

Eagle-I 4.0 cut plate vision system

Eagle-I is the industry leading cut plate inspection system for float glass, offering full conveyor coverage for main line, side leg and offline applications. It allows for the automatic inspection and rejection of all bad glass to user defined tolerances with minimal operator intervention.

Benefits:

- Complete new gantry and system design for new customers

- Retrofit upgrade path for existing customers

- Minimal downtime at installation

- Low maintenance

- Faster troubleshooting of glass loss

- Reduced wastage

- Yield maximization

- Detailed inspection data

Eagle-I 4.0 has been developed using customer feedback to focus on those areas identified as critical to the manufacturing process.

It uses the latest generation of cameras to capture multiple channels of data simultaneously under different lighting conditions with innovate image processing algorithms to optimise the inspection.

- Augmented discrimination between real defects and oil

- Enhanced bottom surface defect detection

- Improved paint mark detection at glass edges

- Better crack detection

- Score mark detection

- Higher resolution to detect finer detail

The upgrade can utilise the existing gantry structure and cabinet to minimise downtime and cost.

A new LED frame drops onto the current brackets, and new single-wire solution cameras & optics fit into the existing housings.

New RAID-based PCs provide faster storage/reliability and large storage with high reliability, with support for the latest generations of Windows.

The Eagle-I 4.0 software writes all inspection data to a SQL database, including information such as edge and defect positions, to enable glass loss to be identified and resolved quickly and efficiently.

- Latest generation cameras

- LED lighting

- RAID PCs

- Multiple signal channels capture simultaneous images under different lighting conditions

- SQL database with Big Data

Contact us to see how we can help you with float glass inspection

Stay informed

Follow our latest news here and stay in touch with our organisation.

Guardian Glass Make Thickness Gauge Investment

Inspection Systems has worked with Guardian glass for over 15 years delivering their mainstay product Eagle-I at the cold end of production. Recently with the next generation of products, Guardian required an inspection system for measuring both the thickness and stress of their float glass. They turned to Inspection Systems as our Thickness Gauge provides…

Get in touch

Get in touch with us today to talk about how we can help you with all your glass inspection needs.